When we talk about Bomber Command, we usually concentrate on the crewmen who flew these bombers - but the role of the ground crew was just as important.

When we talk about Bomber Command, we usually concentrate on the crewmen who flew these bombers. Yet for every p lot, bombardier or navigator, there was an army of ground crew and admin personnel who kept the bombers flying – armourers, instrument fitters, engine and airframe fitters, refuellers, drivers, intelligence and medical staff. The non-flying staff of an average bomber base could number in the thousands.

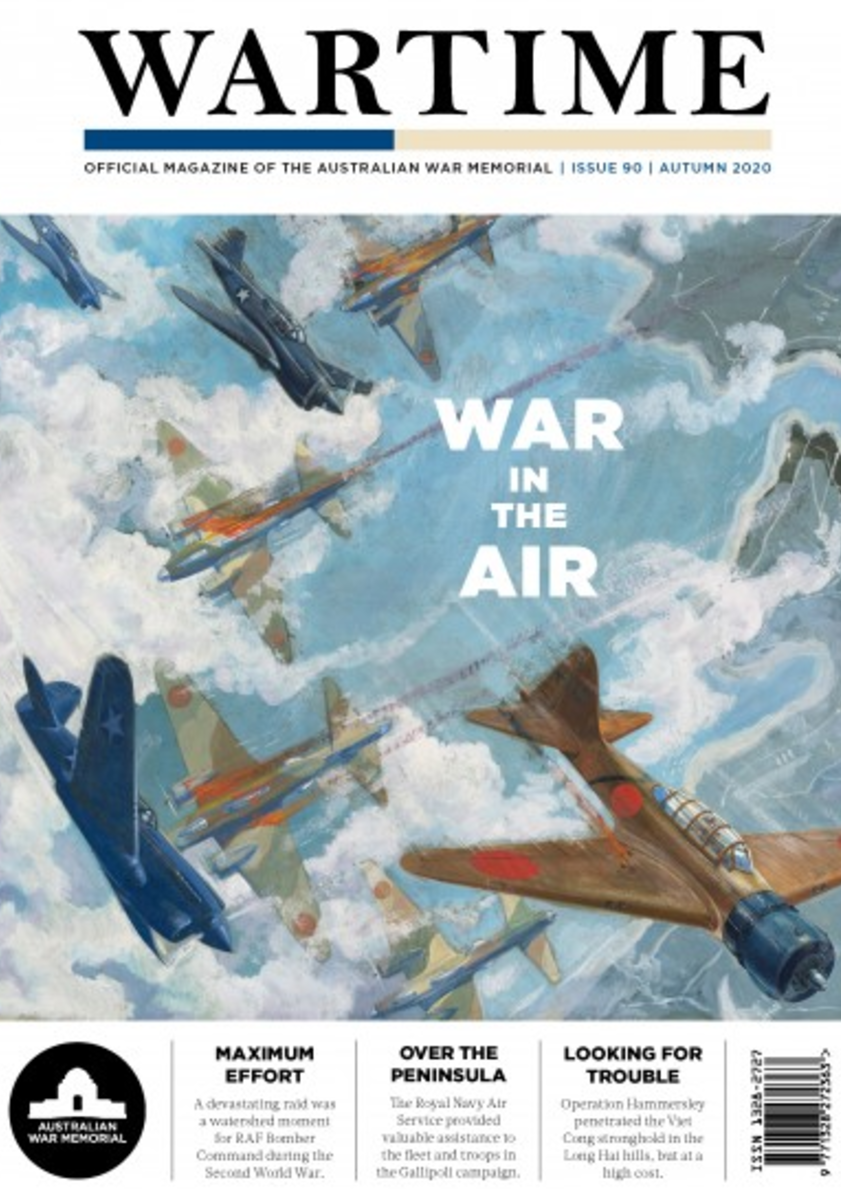

No. 462 Squadron, England, 1944

Among these specialists was the airframe fitter. His basic job was to inspect a returned bomber, locate any damage and repair it. To gain the skills necessary, prospective fitters attended a four-month course at a special technical school. Australia, for example, ran a Fitters IIA (A for airframe) course at the RAAF No.1 Engineering School at Ascot Vale, Melbourne, which taught the fitters the basics of metal folding, shaping and riveting.

When they reached England, they would be taught the specifics of the aircraft for which they would be responsible. For example, Avro ran a course at its Lancaster plant in Manchester for ground crew. With almost 55,000 separate parts making up a Lancaster, learning the construction of one was a massive but vital undertaking.

Group photo of the ground crew of 460 Squadron RAAF. Harold Andrews is on the right, laying on the ground.

With 460 Squadron RAAF, which was formed at Molesworth in Cambridgeshire in November 1941, the ground crews had to learn not only the complexities of the twin-engined Vickers Wellington (until September 1942) but the four-engined Avro Lancaster, which they would service until the end of the war in 1945.

In 2014, we received this unique donation for Corporal Harold Wake Andrews, an Australian airframe fitter with 460 Squadron.

This donation included Andrews’ wartime overalls and his toolbox, which contained his original airframe fitter’s tools, some of them marked with his initials. This was very special indeed.

Overalls (AWM REL48605), tools and toolbox (AWM REL48606) used by Harold Wake "Andy" Andrews.

Lancaster “G for George” (which Corporal Andrews worked on) returned on 20 occasions with minor or major damage, inflicted by flak or fighters; and the damage reveals the sort of repairs that an airframe fitter would have to deal with, preferably before the next night’s mission. If, however, the damage was severe enough, repairs could put an aircraft into the repair shop for weeks, with not only the skin damaged, but the underlying framework as well.

When only on its fourth mission, sea mining off the coast of Sweden on 17 December 1942, “G for George” was shredded by ground fire and flak, which tore a 20-centimetre hole in the starboard wing, as well as cannon holes in an undercarriage door and both wings, and machine-gun damage to the tailplane and in both rudders. Pulled off the flight line for several weeks, “George” didn’t fly again until 16 January 1943 while airframe fitters such as Harold Andrews worked hard to repair the damage.

On 5 September 1943 (on its 52nd mission) “G for George” flew to Mannheim – a round trip of seven-and a-half hours. To avoid being coned by searchlights (and targeted by flak) over the target, the pilot, Flight Sergeant “Cherry” Carter, had put the aircraft into a steep dive at near maximum revs, and the extreme stresses put on the skin popped a whole line of rivets along the wing. Fitters would have to deal with this, and we can see in Andrews’ kit the tools used to accomplish this – a drill to remove the damaged rivets, a hammer to make good the skin if it had been damaged (with a small dolly to support

the skin), a reamer to clean up the rivet holes, and a supply of rivets.

If the skin had been damaged beyond repair, then a fitter would have used the shears to cut away the damaged areas and a new skin would have to be cut and shaped. If the damage was too complex, or the frame suffered stress fractures, a replacement frame would be used. The key to the job was knowing what you could accomplish and adjusting accordingly.

Once the job was completed, Andrews would have to complete a report on the work done and the materials used, so that replacement materials could be restocked.

This set of tools – some modified to suit the job – are a tribute to the men who laboured during the daylight hours to ensure that the men of Bomber Command could fly their bombers night after night.